Research Overview

The efficiency and operational life of sophisticated electronics (e.g., batteries, electronic chips, active wearable or implanted electronics) that enable our digital world are often determined by the materials selected and optimized for those applications. We work to build fundamental tools for solid-state inorganic materials featuring unique chemical, electronic, and structural instabilities within the diverse domain of materials.

Current Focus

Our ongoing research centers on the accelerated design of materials, with a particular focus on high entropy alloys and thermoelectric materials. We aim to develop tools for solid-state inorganic materials that exhibit unique chemical, electronic, and structural instabilities, spanning domains such as:

- Next-generation batteries (e.g., cobalt-free lithium and magnesium-based cells)

- Electrochemical Random Access Memories (RAMs)

- Thermoelectric materials for power generation (e.g., MgSnSiSe, SnSe)

- Computational design of complex metal alloys

The exploration of novel materials in these areas involves diverse approaches, including searching crystallographic databases, modifying known materials, combining materials in heterostructures, and creating entirely new compounds.

Navigating rugged energy landscapes to determine phase stability in materials.

Navigating rugged energy landscapes to determine phase stability in materials.

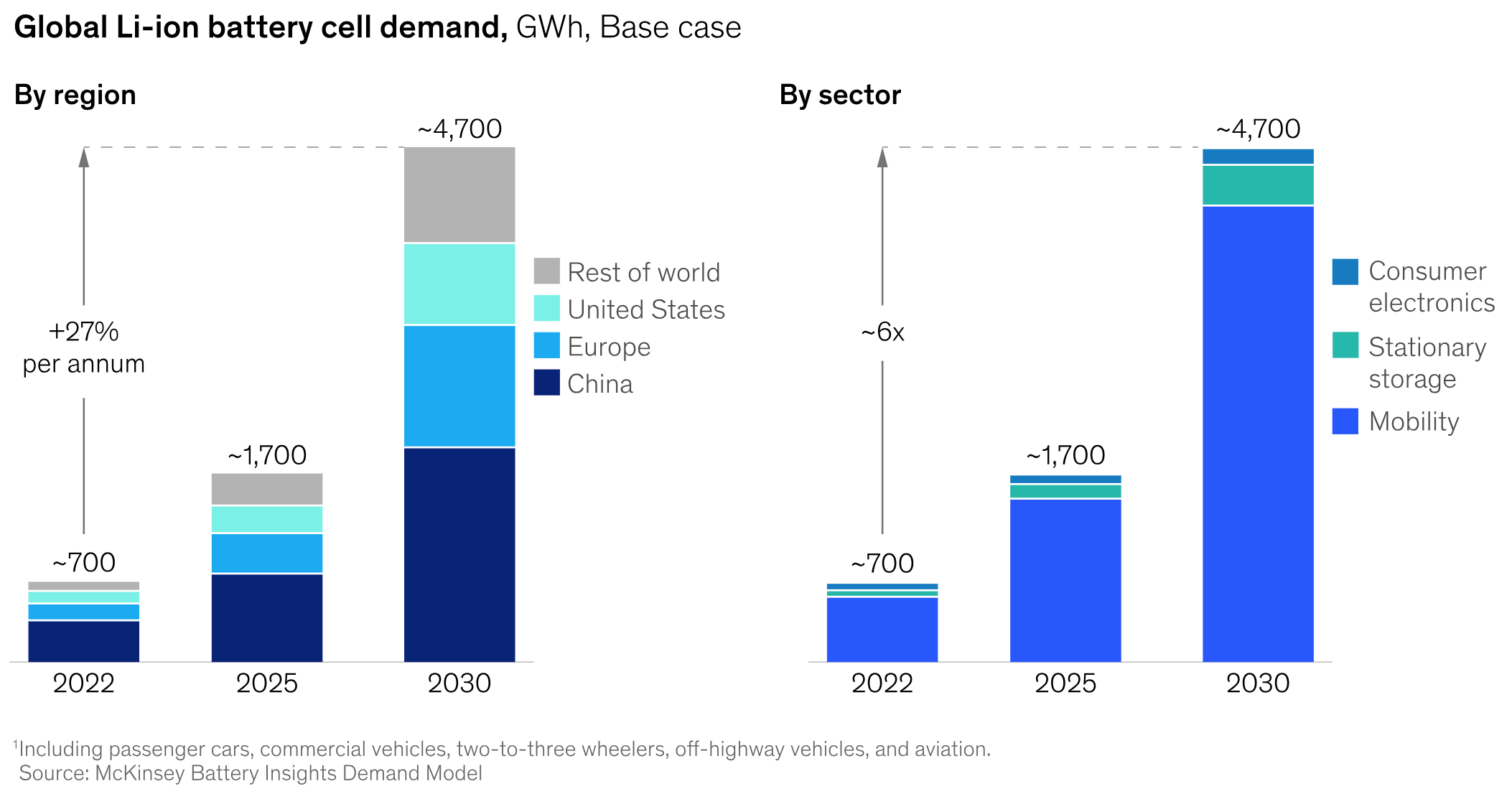

1. Data-driven Design of Battery Cells

The future is electric, and the battery industry plays a crucial role in modern society. The demand for batteries continues to rise as the push towards electrification increases. Our research focuses on optimizing battery chemistries to meet future energy demands while reducing dependency on critical minerals like lithium.

Key Areas of Focus

- Multimodal Data Fusion: Combining multiple sources of data (EIS, CP, XRD, SEM) to predict battery cell performance using machine learning models.

- Uncertainty Quantification: Developing probabilistic models that provide not only predictions but also confidence intervals for battery design decisions.

- Transfer Learning for New Chemistries: Investigating how models trained on one type of battery chemistry can be adapted to predict performance for emerging chemistries.

2. Multi-Physics Modeling of Dendrite-Free Metal-Ion Batteries

Developing magnesium and sodium metal anodes for future high-energy storage devices has emerged as a promising alternative to lithium-ion batteries. Our research investigates strategies to optimize these technologies for high-performance applications.

Key Focus Areas:

- Thermodynamic Considerations: Achieving a balance between energy storage capacity and performance.

- Kinetic Requirements: Ensuring low site-to-site diffusion barriers and facilitating solvation at interfaces for optimal battery performance.

- Multi-Physics Models: Constructing fully coupled mesoscale models to understand the impact of charge, heat, and stress on deposit growth during electrodeposition.

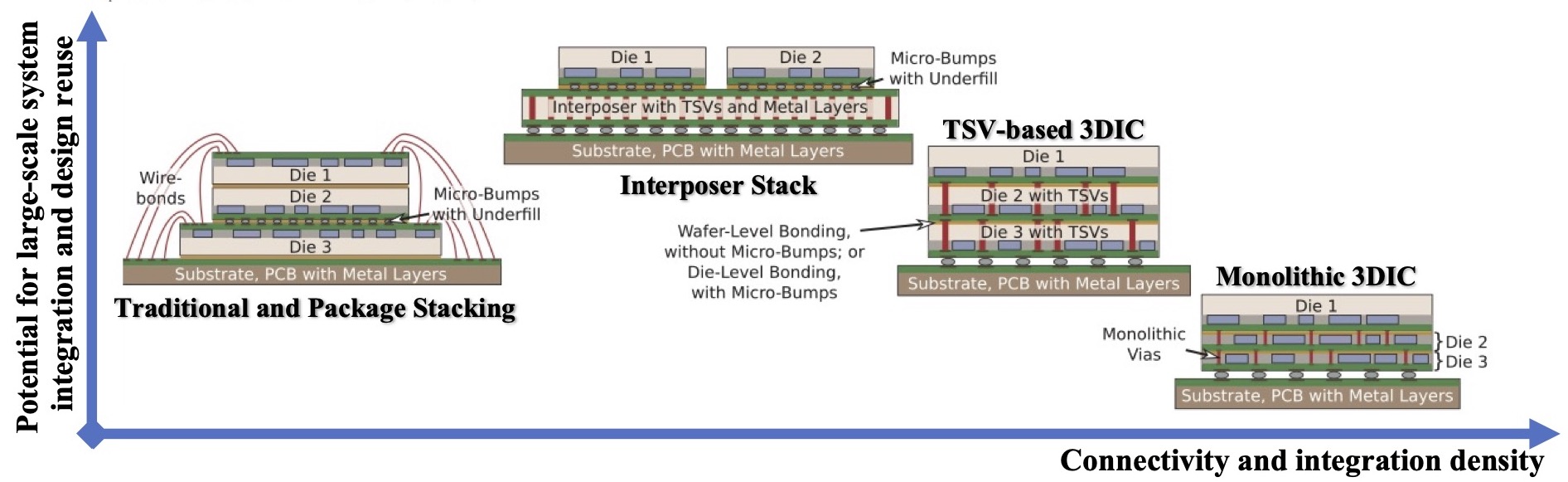

3. Machine-Learning Reinforced Computational Design of Solder Interconnections

Our research focuses on developing machine learning-assisted models for designing solder interconnections in next-generation microchips, reducing energy costs and enhancing material performance.

Key Research Areas:

- Electromigration (EM) and Thermomigration (TM): Addressing critical issues in 3D chip architectures related to electromigration and thermomigration.

- Low-Temperature Solder Solutions: Developing energy-efficient and carbon-reducing solder solutions, such as BiSn-based alloys.

- Microstructure-Sensitive Materials Design: Utilizing phase-field modeling for the analysis of solder interconnects, incorporating deep learning for high-throughput evaluation.

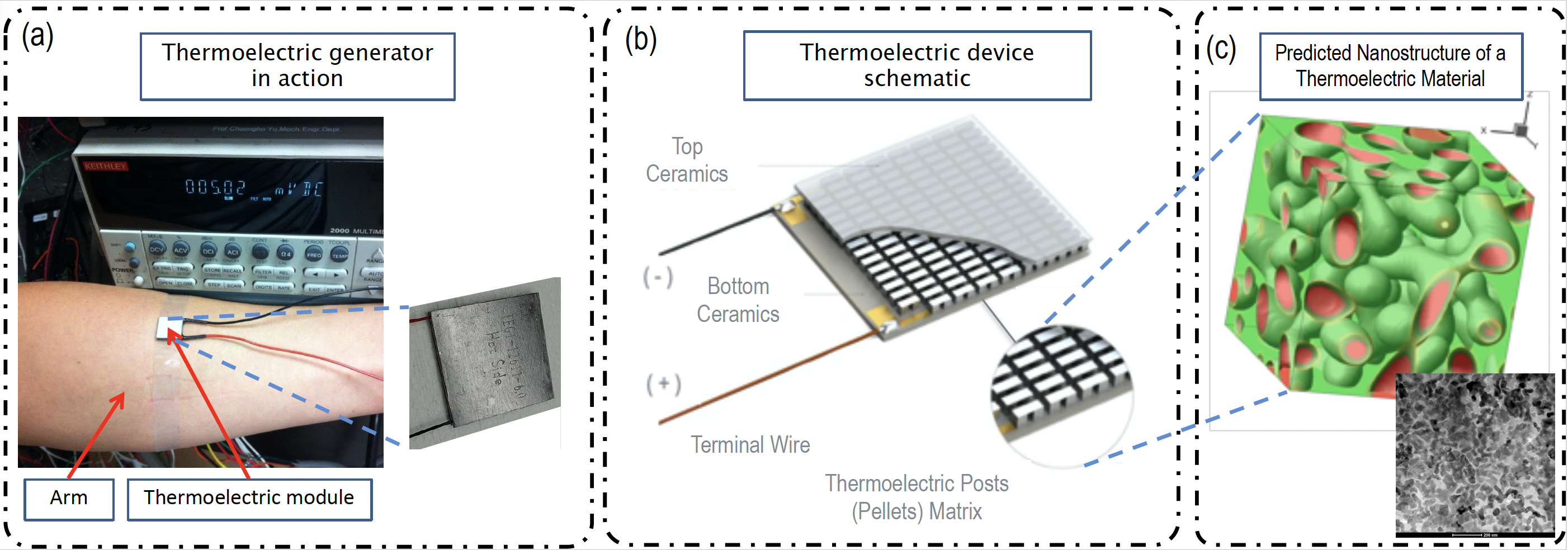

4. Exploring Chemistry/Processing-Structure-Property Relations for High-Performance Thermoelectric Materials

Our research aims to explore the relationships between chemistry, structure, and properties of thermoelectric materials for efficient power generation, using advanced machine learning and optimization techniques.

Key Research Areas:

- High-Throughput Modeling: Developing microstructure-aware models to establish process-structure-property (PSP) relationships.

- Bayesian Optimization (BO): Leveraging BO to optimize material performance through iterative exploration of design space.

- Advanced Machine Learning: Applying deep learning architectures for the prediction of thermoelectric material performance, focusing on microstructure analysis.